Understanding Aluminum Casting: A Comprehensive Guide to Its Applications and advantages

Aluminum casting is a procedure that transforms liquified aluminum into solid kinds through various techniques. This method uses noteworthy advantages, such as lightweight strength and deterioration resistance. It locates applications in various industries, reflecting its flexibility. Nonetheless, comprehending the intricacies of aluminum casting and its ideal methods can considerably influence the top quality of the last product. Discovering these components exposes the true capacity of aluminum casting in contemporary manufacturing.

The Basics of Aluminum Casting

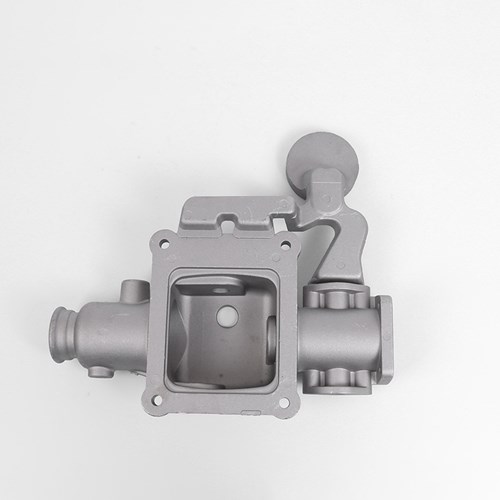

Aluminum casting is a production process that transforms molten aluminum right into strong items via numerous strategies. This procedure starts with home heating aluminum up until it reaches its melting point, permitting it to move right into molds. There are numerous methods of aluminum casting, including sand casting, pass away casting, and investment casting, each ideal for different applications based upon layout complexity and production quantity.

In sand casting, molds are developed using sand, supplying versatility for intricate shapes. Pass away casting entails requiring liquified aluminum into a steel mold under high pressure, resulting in precise and repeatable parts. Financial investment casting, on the various other hand, uses a wax pattern that is covered with ceramic to produce thorough parts.

After the aluminum solidifies and cools, the molds are eliminated, disclosing the ended up products. This casting process is integral in various sectors, including auto, aerospace, and consumer items, enabling the production of lightweight and sturdy elements.

Advantages of Aluminum Casting

One of the essential benefits of aluminum casting depends on its ability to generate lightweight yet solid elements. This distinct mix makes aluminum an optimal selection for different industries, consisting of automotive, aerospace, and consumer goods. The integral rust resistance of aluminum likewise boosts the durability of the cast parts, extending their life expectancy and decreasing the need for upkeep.

Furthermore, aluminum casting permits detailed designs and complicated geometries, which can cause more reliable and cosmetically pleasing products. The material's outstanding thermal and electrical conductivity even more increases its applications, specifically in electronics and warm exchangers.

Additionally, aluminum recycling is highly efficient, adding to environmental sustainability and minimizing production expenses. Generally, the benefits of aluminum casting setting it as a versatile and functional service for producers looking for to enhance performance while minimizing weight and source use.

Common Approaches of Aluminum Casting

While numerous techniques exist for aluminum casting, each technique offers unique benefits tailored to details applications. One of the most common methods include sand casting, pass away casting, and financial investment casting.

Sand casting, recognized for its versatility, uses sand molds to develop intricate shapes and is appropriate for both huge and tiny manufacturing runs. Die casting, on the various other hand, employs high-pressure shot of liquified aluminum right into steel molds, causing smooth surfaces and precise dimensions, making it excellent for mass production.

Financial investment casting, frequently referred to as lost-wax casting, involves creating a wax pattern coated with a ceramic covering. Precision aluminum casting. When the wax is dissolved, liquified aluminum is poured into the cavity, yielding complex designs and outstanding surface finishes

Each of these techniques plays a vital role in the aluminum casting landscape, using certain benefits that satisfy differing production requirements and production scales.

Applications Across Industries

The convenience of aluminum casting methods permits for a wide variety of applications across different industries. In the auto sector, light-weight aluminum parts enhance fuel effectiveness and efficiency, adding to the growing need for electrical automobiles. Aerospace industries utilize aluminum spreadings for their strength-to-weight ratio, guaranteeing safety and resilience in aircraft manufacturing.

The building market gain from aluminum casting via building elements and structural components that resist corrosion and require marginal maintenance. Furthermore, consumer electronic devices suppliers utilize aluminum castings for frames and real estates, balancing aesthetic appeals with functionality.

In the aquatic sector, aluminum castings are favored for watercrafts and marine equipment because of their resistance to deep sea deterioration. The medical area makes use of aluminum castings in surgical instruments and devices, guaranteeing accuracy and dependability. In general, aluminum casting's adaptability enables it to satisfy the varied demands of several sectors, making it a crucial production procedure.

Finest Practices for Effective Aluminum Casting

Effective aluminum casting counts on a mix of mindful prep work, precise implementation, and detailed high quality control. At first, selecting premium aluminum alloys is important, as they straight affect the casting's residential properties and efficiency. Appropriate mold and mildew style is critical, ensuring that it fits thermal contraction and minimizes look these up issues.

Throughout the melting procedure, avoiding and maintaining the appropriate temperature level contamination are essential to attaining a consistent alloy. Additionally, making use of effective putting techniques can improve the filling of molds, reducing the possibility of air pockets or incorporations.

Post-casting, executing extensive check this site out examination techniques, such as visual analyses and non-destructive screening, guarantees that issues are determined early. Moreover, employing extensive high quality control steps throughout the procedure assists keep uniformity and integrity in the final items. By adhering to these finest methods, makers can substantially enhance the success and performance of their aluminum casting operations.

Frequently Asked Concerns

What Safety and security Steps Should Be Taken During Aluminum Casting?

How Can Issues in Aluminum Castings Be Decreased?

Defects in aluminum spreadings can be lessened with careful mold and mildew layout, correct temperature level control, making sure clean steel, utilizing proper pouring techniques, and performing extensive examinations to recognize and deal with problems prior to finalizing the casting process.

What Is the Ecological Impact of Aluminum Casting?

The ecological influence of aluminum casting includes energy-intensive processes, greenhouse gas discharges, and resource extraction issues. Nevertheless, developments in recycling and lasting methods can minimize these effects, promoting a more environment-friendly method to aluminum production.

Can Aluminum Casting Be Recycled?

Yes, aluminum casting can be recycled successfully. The recycling process needs considerably less energy compared to primary aluminum production, making it an eco friendly option that adds to source preservation and decreased carbon exhausts.

What Are the Prices Connected With Aluminum Casting Processes?

Expenses useful reference linked with aluminum casting processes consist of product expenditures, labor, equipment maintenance, energy intake, and mold and mildew fabrication. These variables can differ substantially based on manufacturing range, intricacy of styles, and details manufacturing strategies used.

Aluminum casting is a procedure that changes molten aluminum into solid kinds through numerous strategies. Aluminum casting is a production process that changes molten aluminum right into strong items through different methods. While various methods exist for aluminum casting, each approach offers unique advantages tailored to certain applications. The ecological effect of aluminum casting consists of energy-intensive procedures, greenhouse gas exhausts, and source extraction concerns. Costs linked with aluminum casting processes consist of product expenses, labor, equipment upkeep, power intake, and mold fabrication.